K Value Formula Of Pvc

Pvc is a strong lightweight polymer commonly used in construction.

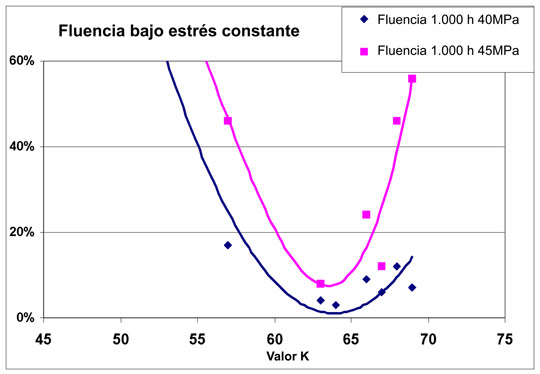

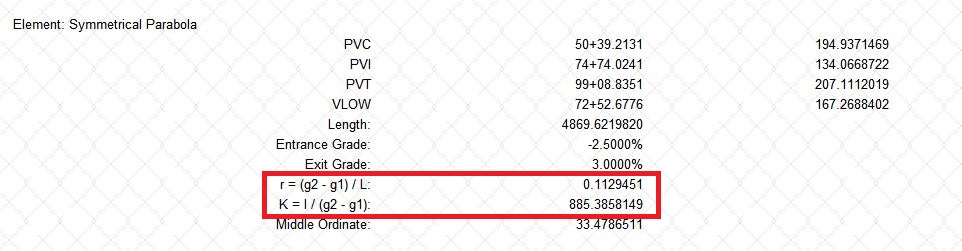

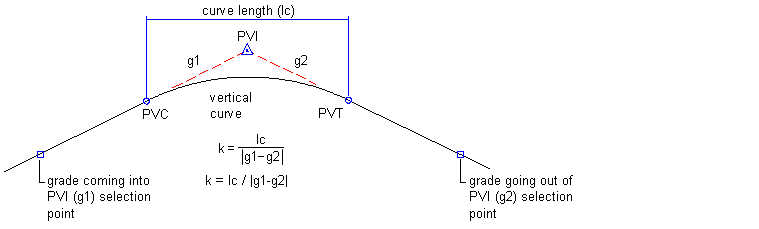

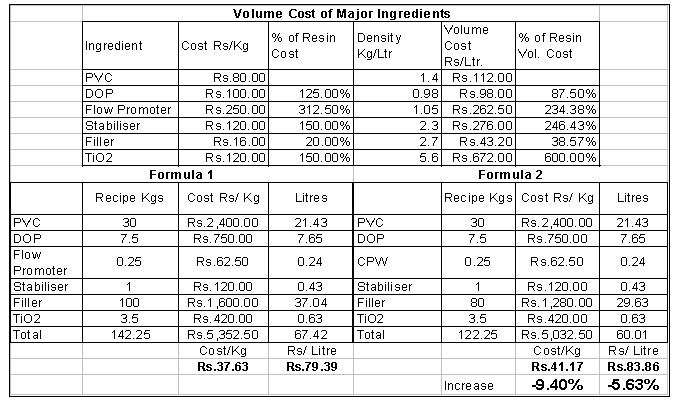

K value formula of pvc. 125 pvc resin k value 60 œ 65 and pvc resin k value 70 were used. The additives used were tribasic lead sulphate b lead stearate glyceryl monostearate acrylic for process aid di isoctyl. Formula for calculating head loss from k values. K value is simply shorthand for thermal conductivity.

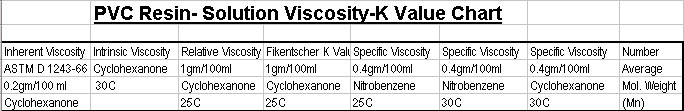

Thus for k value of 55 6 the viscosity would be α 55 6 3 4. Is expressed by the following formula. The most commonly used k value in europe is the fikentscher k value referenced. Since k value is a measure of extent of polymerization for pvc we can say that its viscosity α k value 3 4.

Most of us will be familiar with it from pvc pipes used for domestic plumbing. Iso 1628 part 2 is the most common method. K value method and typical values. The time rate of steady state heat flow through a unit area of a homogeneous material induced by a unit temperature gradient in a direction perpendicular to that unit area.

K 57 is medium for injection molding k 67 is medium high for rigid extrusion k 70 is higher for plasticized extrusion or calendering. The pvc is dissolved in cyclohexanone prior to measurement. K value relates. The astm standard c168 on terminology defines the term as follows.

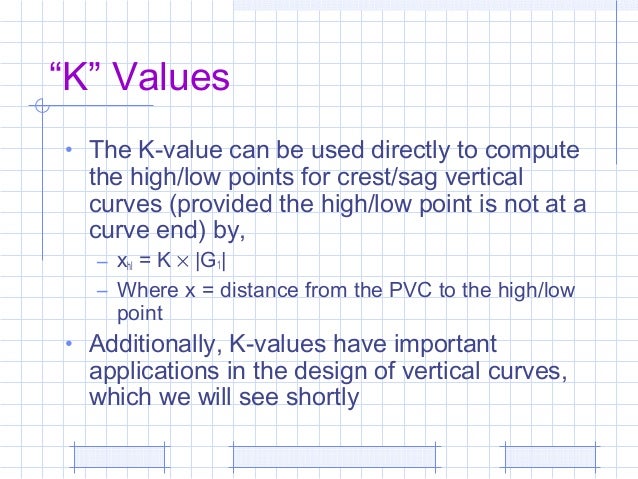

The influence of k value and plasticizer type on the rheological behaviour of plastisol used in coated. K value viscosity is an empirical parameter closely related to intrinsic viscosity often defined in slightly different ways in different industries to express viscosity based estimate of statistical molecular mass of polymeric material used particularly for pvc. It is in some ways similar to the equivalent length method and the two may be equated by the formula below. The velocity head method is named as such because it represents the pressure loss through a fitting as the equivalent number of velocity heads.

In order to test the k value of the pvc it is necessary to dissolve it first. K value is an indicator of molecular weight. The second category was the additives used for improving the qaulity process conditioning of the pvc formulations.